Allocation And Apportionment Of Overhead To Cost Centres

Personnel Department could be allocated to the Information Systems Department. Personnel Department are allotted solely to the Information Systems Department. Assembly Department are allocated https://cryptolisting.org/blog/how-do-you-allocate-service-department-costs-to-production-departments to the Information Systems Department and the Personnel Department.

Allocation Of Overhead Expenses:

First, the Definitions and Uses of Cost Allocation and Cost Approtionment. Secondly, assigning acceptable portions of the totals to particular allocation of factory service department costs to the production departments is necessary to: person product items, organizations, or events.

Advantages Of Departmentalization Of Overhead Expenses:

Therefore, there could be zero equivalent items with respect to half HH887 within the work in course of inventory at the finish of April. Machining Department can be allotted to the Information Systems Department. Personnel Department could be allotted to the Assembly Department and the Machining Department.

- This technique does not take into impact the truth that a service division could also be offering providers to different service departments too.

- It is the one technique that absolutely accounts for the reciprocal provision of providers among departments.

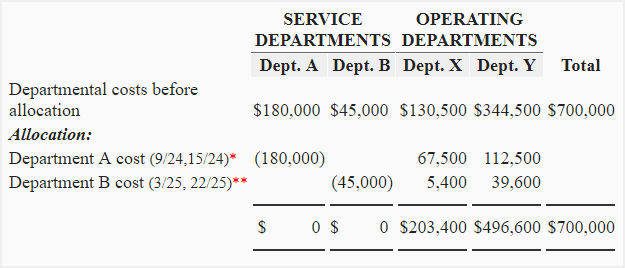

- Use the direct method to allocate help division costs to production departments, and decide the predetermined manufacturing overhead charges for the 2 production departments.

- In the direct methodology of cost allocation, the allocation of the service departments is done to the production departments.

- As stated in the previous answer, underneath the reciprocal providers method all of the support departments’ costs are allotted among the entire departments that use the various help departments’ output of services.

- Cost is allocated only to the production or the working departments.

Apportionment Of Overheads

Similarly, the cost of repairs and upkeep of a selected machine ought to be charged to that specific department wherein the machine is situated. Power, if separate meters are supplied at every price centre and fuel oil for boilers are different examples of allocation. So, the time period allocation means the allotment of the whole merchandise with out division to a selected division or price centre. The number of such departments and their number will depend on the character of industry, kind of labor carried out and the size of the factory. For instance, in Steel Rolling Mill, Hot Mill, Cold Mill, Pickling Shop, Annealing Shop, Hardening, Polishing and Grinding are the manufacturing departments.

A. Personnel Department can be allocated to the Information Systems Department. C. Personnel Department are allocated solely to the Information Systems Department. prices of the Machining Department are allocated to the Assembly Department. This basis is used for the apportionment of energy expenses.

ultimately applied by the person departments to the models allocation of factory service department costs to the production departments is necessary to: produced.

If all machines operate eight hours a day, to calculate this number, multiply eight hours occasions five days per week, then multiply that by 52 weeks. If two machines operate full-time in the machining department and one machine operates full-time within the ending department, then machine hours equate to 4,a hundred and sixty and a couple of,080 respectively. Product production ought to be analyzed first from the actions that go into it (for instance, manufacturing machine set up and equipment maintenance). These operations normally occur only after manufacturing many product items.

Machining costs are $33.65 an hour and finishing costs are $28.85 an hour. Find the whole https://cex.io/ period of time each division runs per yr.